New Daytona Coupe Build With Modern Window Development

You asked for it, we’re building it; modern windows in a Daytona Coupe Replica. Tom from Colorado visited our factory and took a spin in our Signature Series Daytona Coupe. The moment he got out of the beautiful car he was ready to make a purchase on a beautiful pearl white, blue stripe, and orange accented Daytona Coupe replica.

It all started at Barrett-Jackson 2019 in Scottsdale Arizona, where Tom visited our booth, showed a heavy interest in our twin-turbo Daytona and even had the opportunity to sit in it. We knew and he knew that he wanted to have one built, but just couldn’t pull the trigger on the spot. We kept in touch with Tom throughout the year, checking in to see how he was doing and he eventually told us he wanted to run by the shop on his way to an air show with his nephew. Tom was looking between a Superformance Daytona Coupe replica or a new custom built FormaCars Daytona Coupe replica.

We took Tom and his nephew around our 35,000 sq ft facility and showed him all the projects we were working on. Then, we took him out for a spin. Tom got a ride in an 800 HP Twin Turbo Daytona & his nephew received a ride in a 435 HP Cobra. Make sure to watch the end to see their reactions :). Check out some of the footage below:

We worked with Tom to customize a build that was suited to him and made sure to accommodate all of his needs.

Tom wanted a supercharged FormaCars Signature Series Daytona Coupe replica with power windows and custom seats. Prior to Tom purchasing his Daytona he had told us that he loves the look and sound of the old classic cars, but really needs the modern amenities. We don’t blame him! The signature series is packed full of modern amenities.

We ordered Tom’s kit from Factory Five Racing and started the development of windows prior to the kit pickup and arrival. Here are some images below picking up Tom’s Daytona along with another Cobra we will be working on.

We used a laser scanner to scan the frame of the Daytona Coupe (we were also scanning the Cobra to build a stretch version for tall people). We use this technology, so we can accurately engineer a solution that fits seamlessly and looks natural on the classic vehicle. It should look like it is part of the original design. You can see a quick video of this below:

After we 3D scan the doors and body we can work with the models in our engineering software to develop mock-ups and working models for prototyping. Here are some of the 3D modeling images:

We prototyped the windows using our 3D printers and as we iterated on our prototypes we started to CNC finished products with billet aluminum.

Here is a video of one of the early prototypes on the Daytona Coupe windows.

Once we had our windows just right we took them to the our CNC and went into production. Here is a partial video of that looks like. We take precision seriously.

Meanwhile, we are actively fitting the body to the frame as well as finishing the body getting it ready for paint. This is the most important part - paint work is all about prep. This is the reason people walk up to our cars and their jaws drop. They look beautiful standing right next to them. We often get compliments on our paint jobs and this is the reason why. We prep and we prep well.

Below are photos of the Daytona after the first round of paint prep. At this point we will start mounting fixtures, like lights, etc.

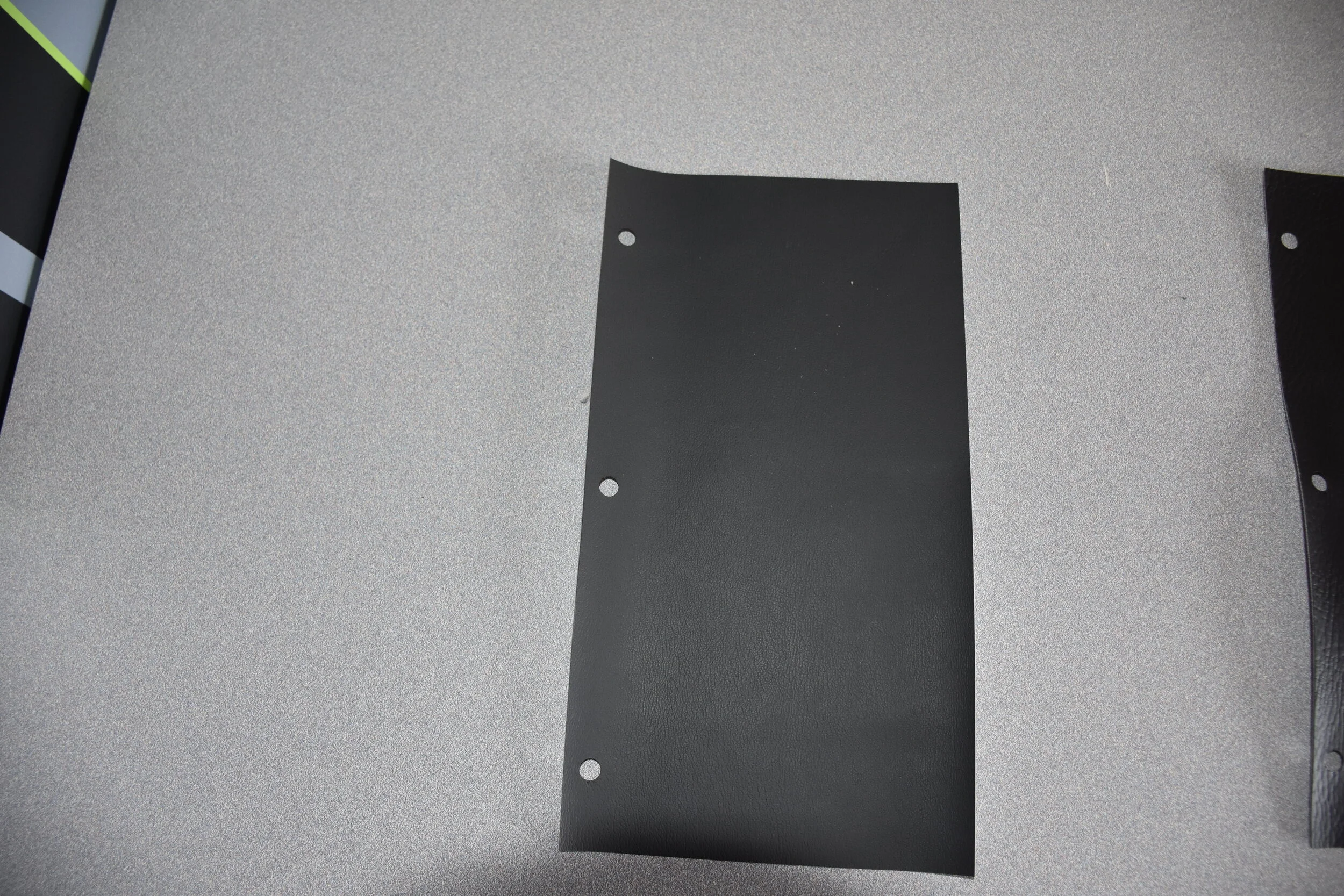

Tom wanted a pearl white car with blue stripe and orange accents. We painted templates with the actual colors, so there is no mistaking what the car will look like and sent them to Tom for his review. We went through three variations of the orange. Here are two variations of the templates we created inside a binder where we collect and store the details of his build journey. We will provide this to him with the delivery of his beautiful car.

We went through some variations of the paint design theme with Tom to make sure he was satisfied. Below are some of the variants.

After we received Tom’s final approval on the exterior color theme, we were able to start brainstorming on interior colors. We gathered a lot of material to test some ideas and send them his way to capture his dream.

This build includes an Edelbrock Supercharger sitting on top of a Gen 2 Ford Coyote engine with an MT82 6-speed transmission. We had to upgrade to a McLeod RST Street Twin Clutch Kit to be able to handle the additional power of the supercharger; otherwise the engine will drive right through the original clutch.

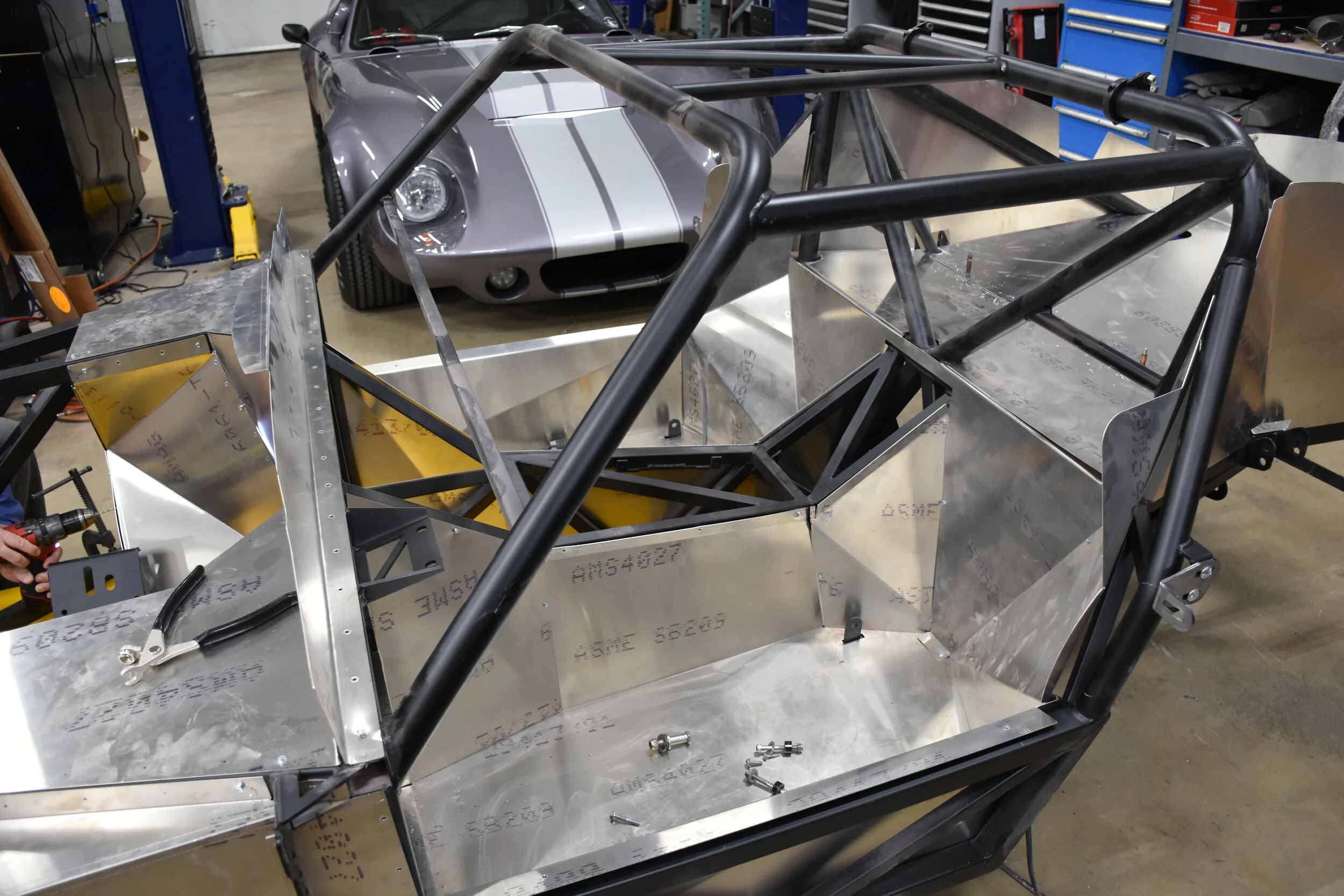

The frame gets 100’s of holes drilled into it to accommodate all the sheet metal. All of our sheet metal is powder coated after it is fitted to the frame. It’s tedius work, but worth it when you look at the finished product. After powder coating all the of the sheet metal is riveted in place as well as secured with M1 Structural Adhesive to prevent any vibration and provide additional strength to the rivets.

While the sheet metal is at powder coat, the suspension, brakes, lines, and more are starting to be added to the frame. You’ll see that the calipers are powder coated to match the paint theme. In addition, you’ll see a few pictures with some of the powder coated sheet metal installed.

Ahh, the paint is complete. Nothing like a fresh paint job on a new car. The character of your car really comes to life. Here are some preliminary images of the finished paint work.

We aren’t done yet and there will be a lot more to come! Continue following this blog post for additional progress. Leave a comment or share this with your friends!